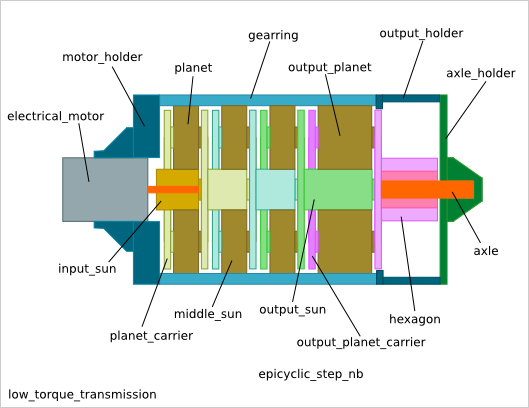

38. Low_torque_transmission Design¶

Ready-to-use parametric low-torque-transmission design. It is a reduction system based on a train of epicyclic-gearing. The design includes the electric-motor holder for a cylindric or square format. The output is an hexagon on which you can plug a gearwheel.

low_torque_transmission design characteristics:

- train of epicyclic-gearing of n-step (to reach a high reduction ratio)

- same epicyclic profile for the n-step (to get a simple gearring-holder desing)

- same epicyclic width for the n-1 first steps (only the last step might at its yield limits)

- epicyclic with 3 planets (for a more stable planet-holder)

- coaxial electric motor at the input (for a compact and reliable transmission)

- hexagon at the output (for an exchangeable output gearwheel)

- output axle hold on one side only (because on the other side, there is already the motor)

To get an overview of the possible low_torque_transmission designs that can be generated by low_torque_transmission(), run:

> python low_torque_transmission.py --run_self_test

38.1. Low_torque_transmission Parameters¶

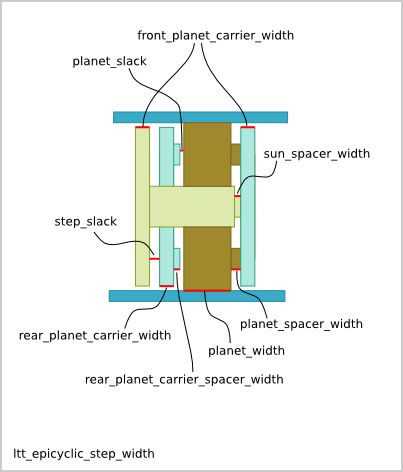

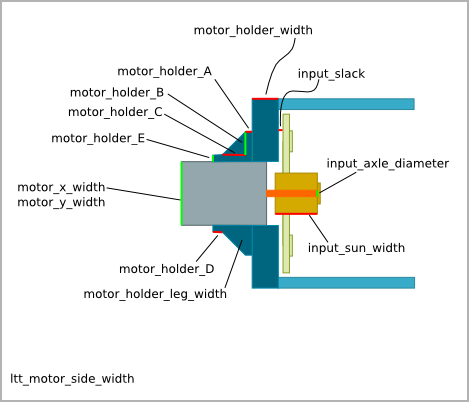

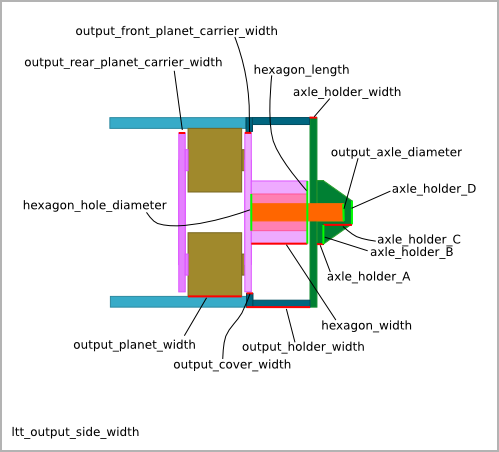

The Low_torque_transmission is composed of the following parts

The low_torque_transmission inherits the parameters from the Epicyclic Gearing Design. The parameter epicyclic_step_nb sets the number of epicyclic-steps. Most of the other parameters are related to the extrusion size in the z-direction.

38.2. Low_torque_transmission Parameter Dependency¶

38.2.1. hexagon_width¶

The output_hexagon must into the output_holder. But also the output_front_planet_carrier_width must be inside the output-cover to guarantee enough slack between the *output_planet and the output_cover. So we get the relations:

output_cover_width + hexagon_width > output_holder_width

hexagon_width < output_holder_width

38.2.2. input_slack¶

The input_slack parameter sets some play between the motor_holder and the first rear_planet_carrier. Notice that this value is affected by the length of the output axle.