14. Box Wood Frame Design¶

14.1. Box wood frame presentation¶

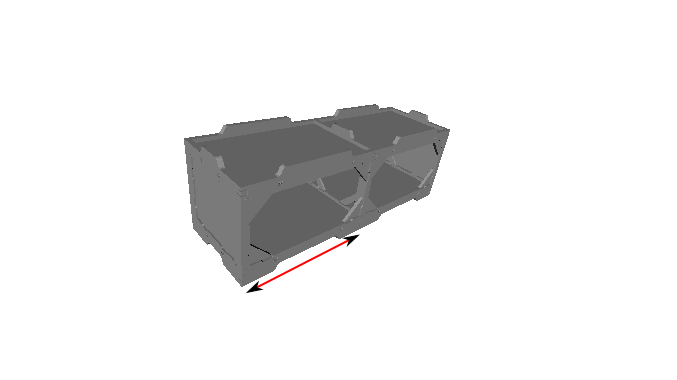

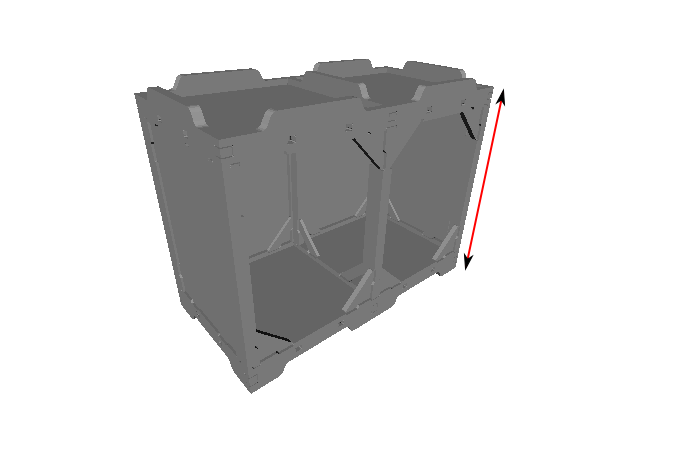

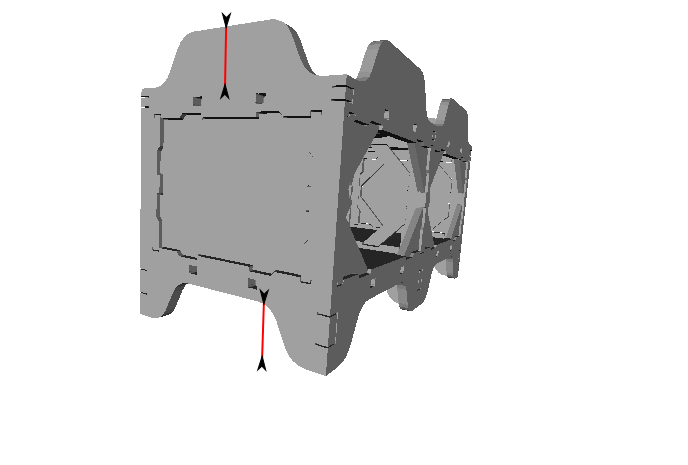

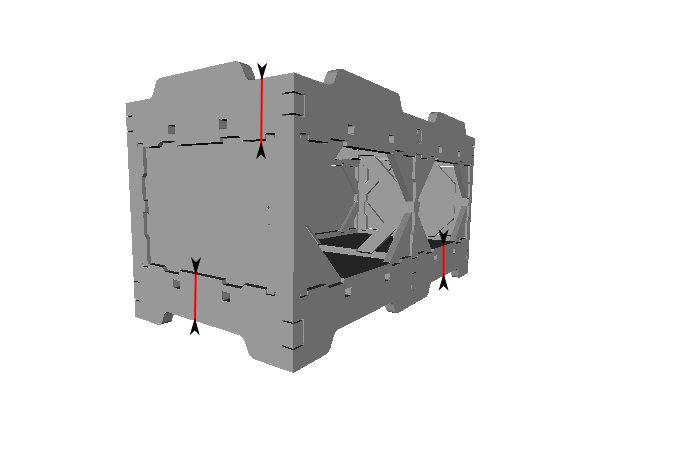

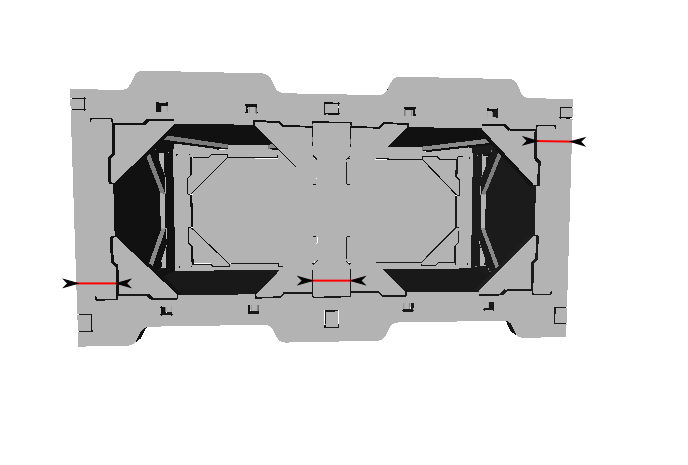

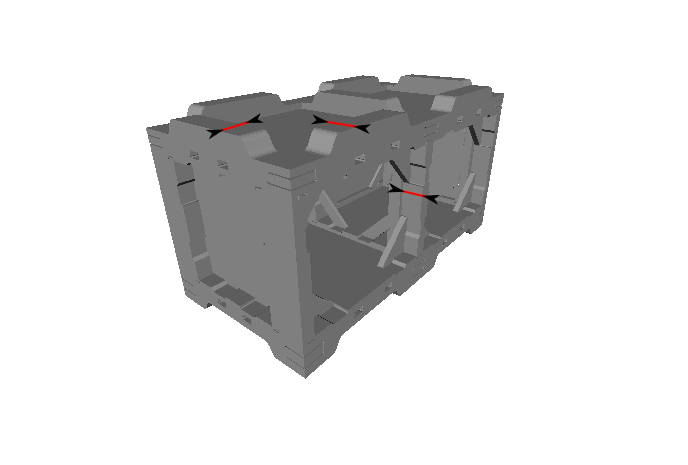

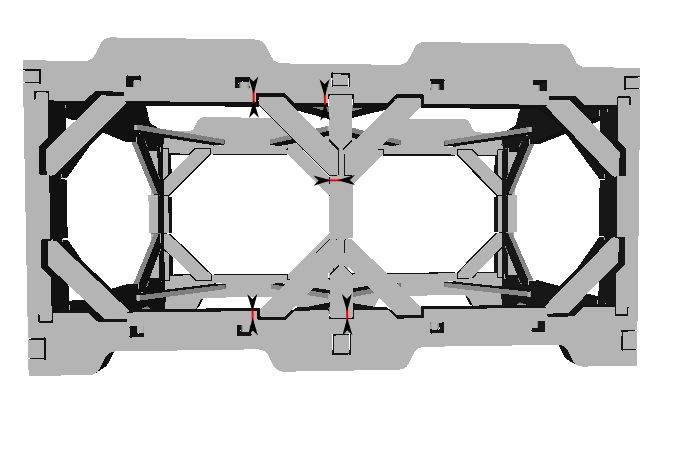

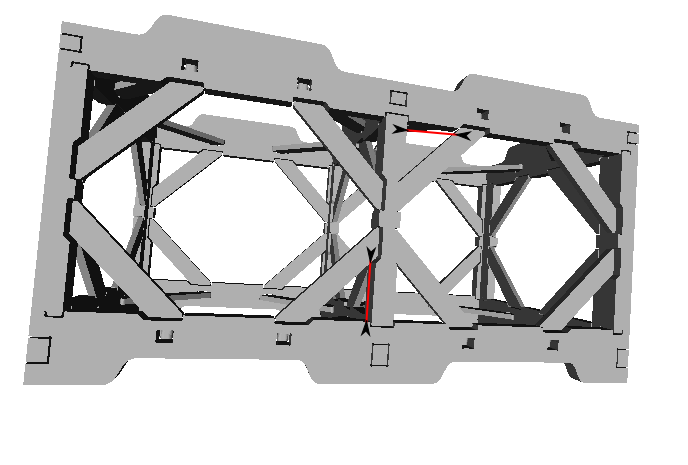

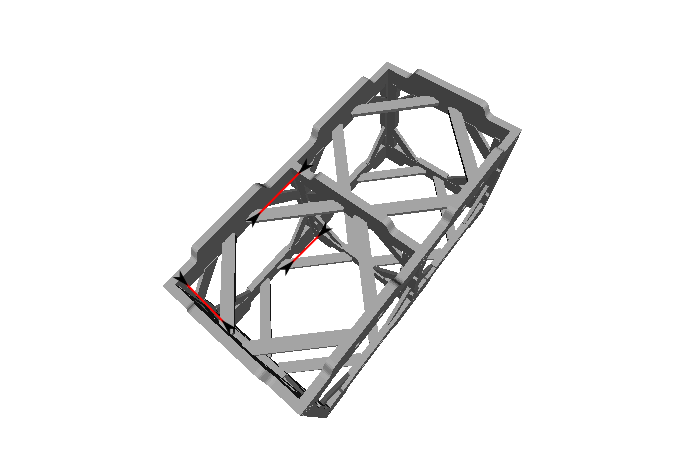

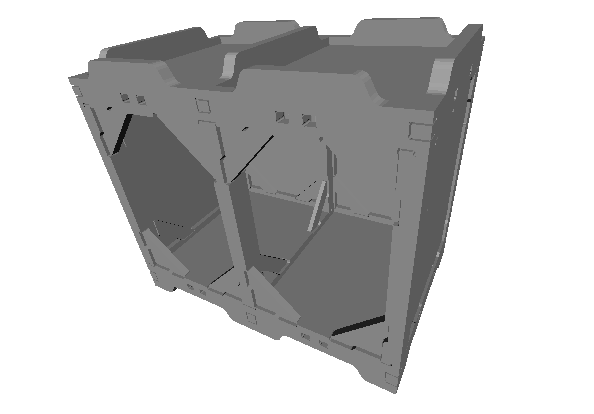

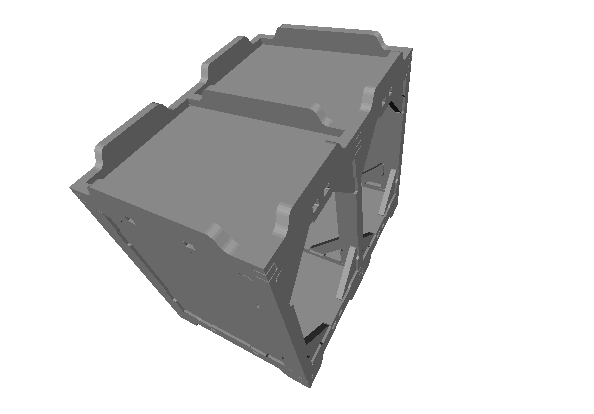

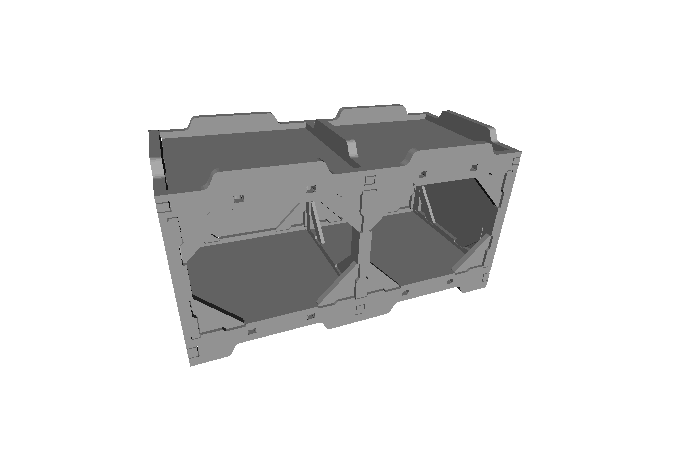

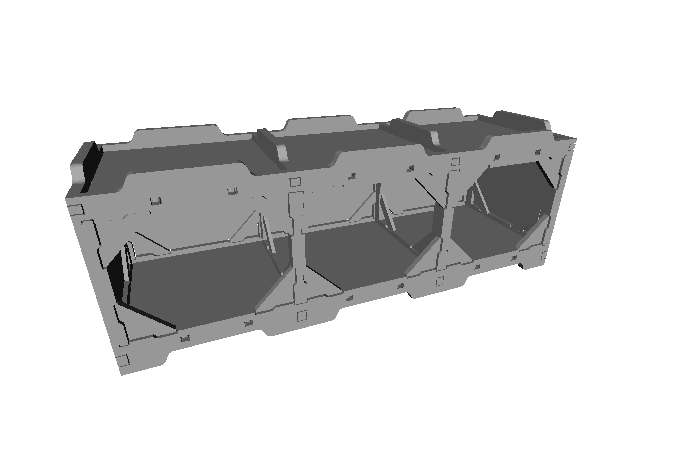

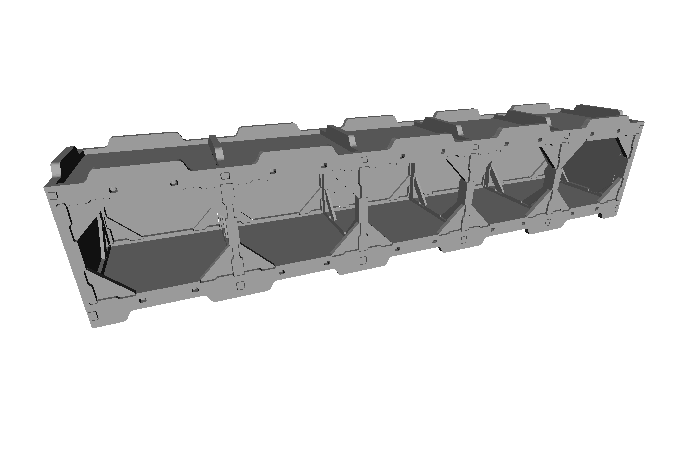

Box wood frame is the name of this piece of furniture:

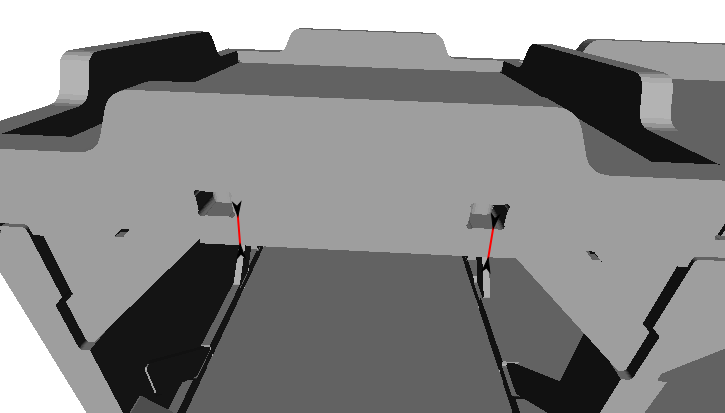

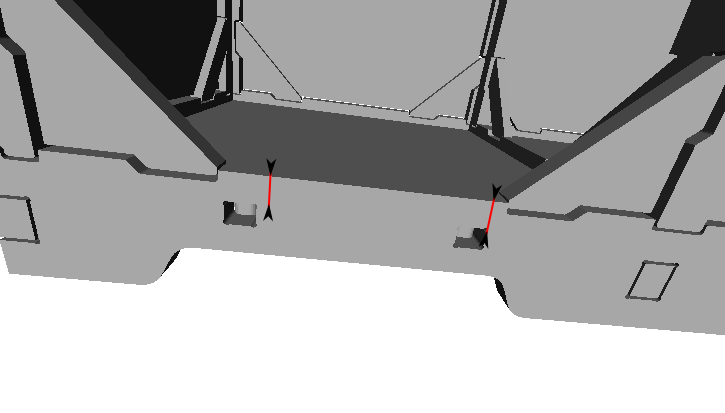

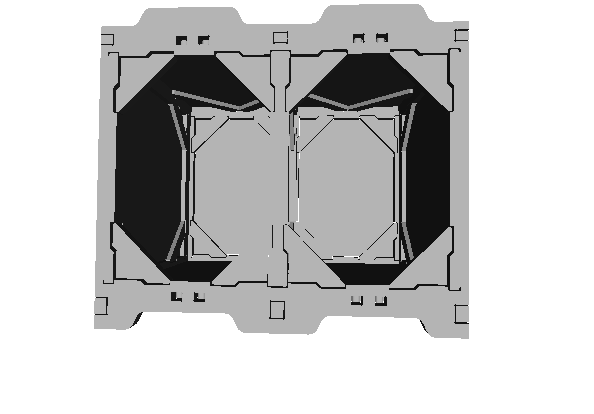

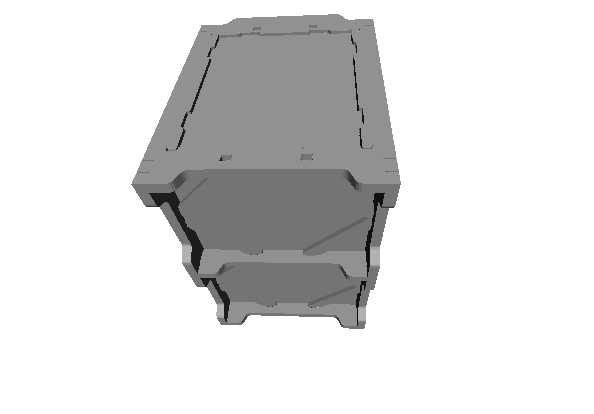

Its main characteristic is its top and bottom fittings that lets pile-up a Box wood frame over an other:

This pile-up functionality has several goals:

- split the manufacturing of large wardrobe into several small modules

- make easier the move of furniture

- be part of the structure of straw houses.

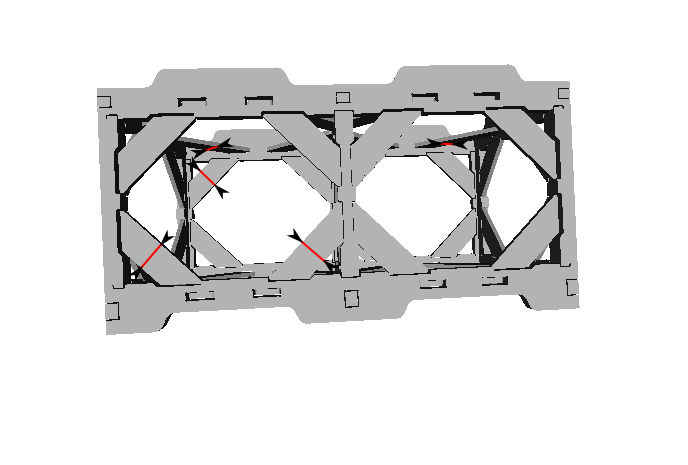

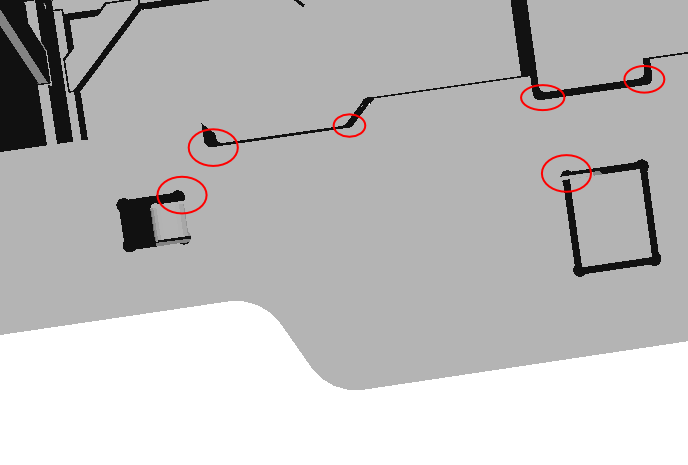

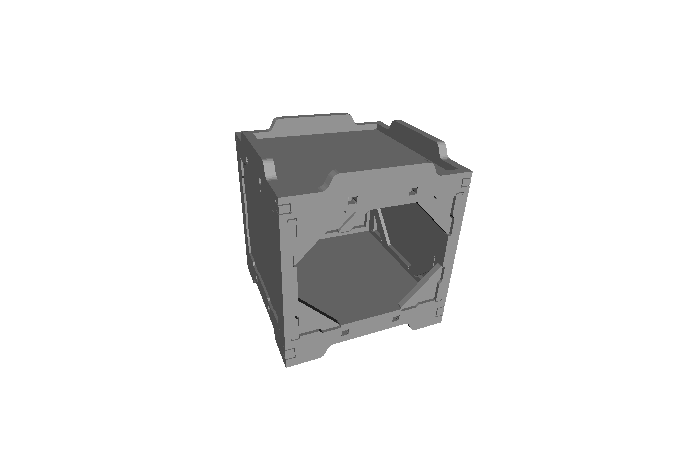

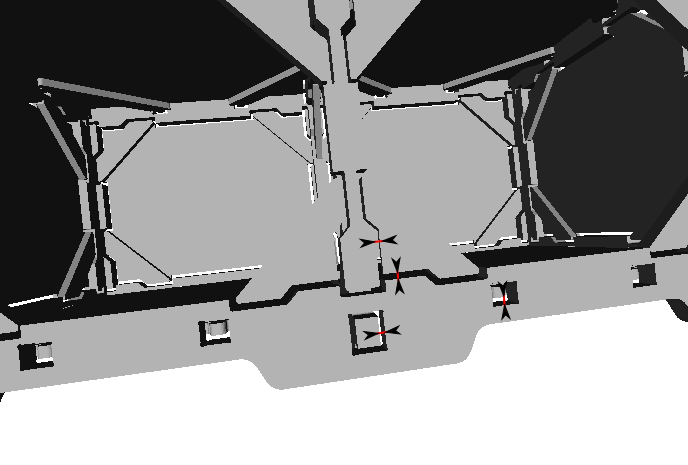

The Box wood frame design uses complex and precise recessed fittings to assemble the planks. So the cuts of the planks must be done with a CNC or with a manual wood router and templates. Then the planks can be glued together.

14.2. Box wood frame creation¶

After installing FreeCAD and the Python package Cnc25D as described at the paragraph Cnc25D Installation, run the executable cnc25d_example_generator.py in the directory where you want to create the Box wood frame:

> cd /directory/where/I/want/to/create/a/box/wood/frame/

> cnc25d_example_generator.py # answer 'y' or 'yes' when it asks you to generate the example box_wood_frame_example.py

> python box_wood_frame_example.py

After several minutes of computation, you get plenty of DXF and STL files that let you manufacture a Box wood frame. Read the text_report.txt file to get further information on your generated Box wood frame and on the descriptions of the other generated files. Use LibreCAD to view the DXF files. Use MeshLAB to view the STL files:

> librecad bwf37_assembly_with_amplified_cut.dxf

> meshlab # import bwf36_assembly_with_amplified_cut.stl

> less bwf49_text_report.txt

Your Box wood frame has been generated with the default parameters. You may want to changes these parameter values to adapt them to your need. Edit the file box_wood_frame_example.py, change some parameters values, save your changes and run again:

> python box_wood_frame_example.py

Now you get the Box wood frame design files according to your parameters.

14.3. Box wood frame parameters¶

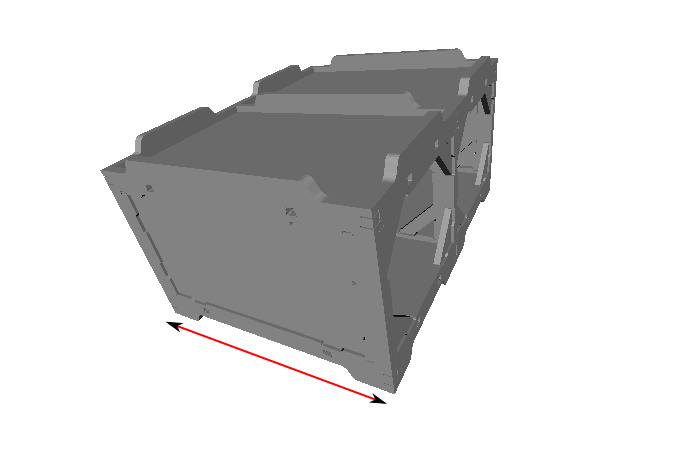

14.3.2. bwf_box_depth¶

bwf_box_depth default value : 400.0

recommendation: Keep bwf_box_depth = bwf_box_width to get more pile up possibilities.

14.3.15. bwf_module_width¶

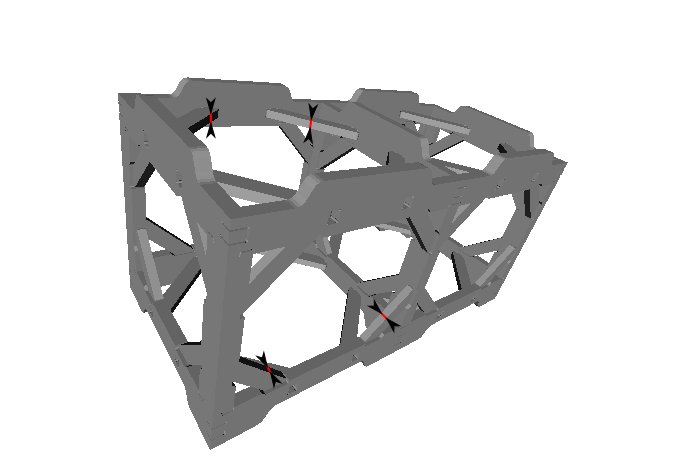

bwf_module_width default value : 1

bwf_module_width = 1

bwf_module_width = 2

bwf_module_width = 3

bwf_module_width = 5

14.3.17. bwf_cutting_extra¶

bwf_cutting_extra default value : 2.0

Note: The parameter bwf_cutting_extra doesn’t affect the cnc cutting plan. It just help to see the junction between the plans.

14.3.18. bwf_slab_thickness¶

bwf_slab_thickness default value : 5.0

The slabs are the skin of your box wood frame. Set the slab thickness to the available plywood thickness of your supplier. Try to keep this relation:

bwf_plank_height > bwf_d_plank_height + bwf_slab_thickness

14.3.19. bwf_output_file_basename¶

bwf_output_file_basename default value : “”

Set the parameter bwf_output_file_basename to a not-empty string if you want to generate the output files. The box_wood_frame_example.py generates many files. These files can be generated in a directory or be identified by a common basename. The generated text file text_report.txt described all generated files.

Output file base name example:

bwf_output_file_basename = "my_output_dir/"

bwf_output_file_basename = "my_output_dir/my_output_basename"

bwf_output_file_basename = "my_output_basename"

14.4. Box wood frame conception¶

The notes relative to process of conception of the Box wood frame are available in the chapter Box Wood Frame Conception Details.

14.5. Box wood frame manufacturing¶

As you can see in the design files, the outline of the planks are quiet complex. Those many recessed fittings enable a solid assembly. To cut the planks precisely according to design files you have two methods:

- Use a 3-axis CNC

- Use a manual wood router and templates for each type of planks.

Notice that you need a CNC to make the templates.

The CNC method is well adapted when you want just few pieces of Box wood frame. The planks are cut in large plywood slabs (long and wide). This increase the final price of a Box wood frame module.

After getting the templates fitting your Box wood frame parameters, you can use a manual route to duplicate the planks. As raw material you can use solid wood plank (long and narrow). This is cheaper and provide a stronger assembly.