17. Gear Guidelines¶

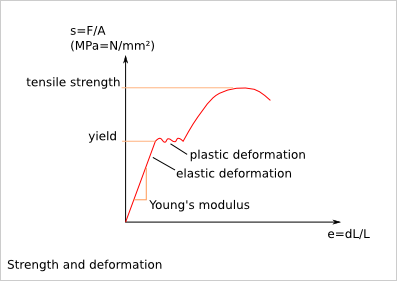

17.1. Strength and deformation¶

17.2. Gear module¶

The gear module defines the size of a gear tooth. Two gearwheels working together must have the same gear module:

circular_pitch = Pi * gear_module

Per default, the tooth height is defined with the gear module:

addendum_height = gear_module

dedendum_height = gear_module

tooth_height = 2 * gear_module

A small gear module generates less friction and then provides a better energy transmission efficiency. A large gear module supports higher efforts:

Module sizing formula in the literaure:

m>2.34*sqrt(T/(k*Rpe))

with:

T = tangential effort on the tooth = F*cos(a)

torque = C = d*F

d = R*cos(a) (R = primitive radius = Z*m/2)

T = F*cos(a) = C/d*cos(a) = C/R

k = tooth width coefficient (usually k=8 or 10)

tooth width = b = k*m

Rpe = Re/s

Re = Yield = elasticity limit

s = security coefficient